Vacuum metallurgy is playing an increasing role in our days, thanks to the development of scientific technology. The number of those practical alloys increased steeply in the recent years, for the production of which in many cases precision, well controlled and reproduceable production technology is needed. These alloys are widely used for scientific research, and they are also used in electronics, and also in the car and airplane industry.

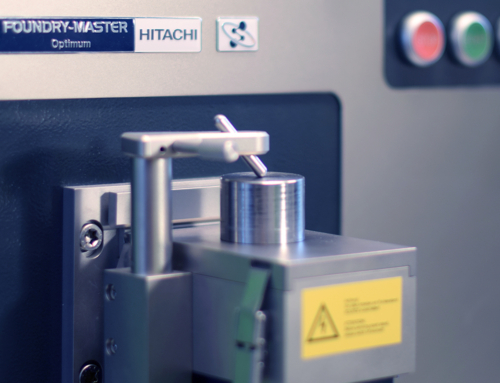

Our company, thanks to its infrastructure is able to produce special alloys in vacuum and inert gas media, with the aid of our vacuum induction melting equipment, with using melting crucibles with graphite, boron-nitride, aluminium oxide or even cold walls, adapted to the properties of the components of the given alloy. The high frequency induction equipment used for melting generates vortexes within the melt, which blend the melt perfectly, thus ensuring its homogeneous composition. Our experts may prepare even jointly with the customer the melting and casting plan, with taking into consideration the special customer demands. Our work is also facilitated by a precision weight scale of 100 microgram resolution, and a high tech optical emission spectrometer.