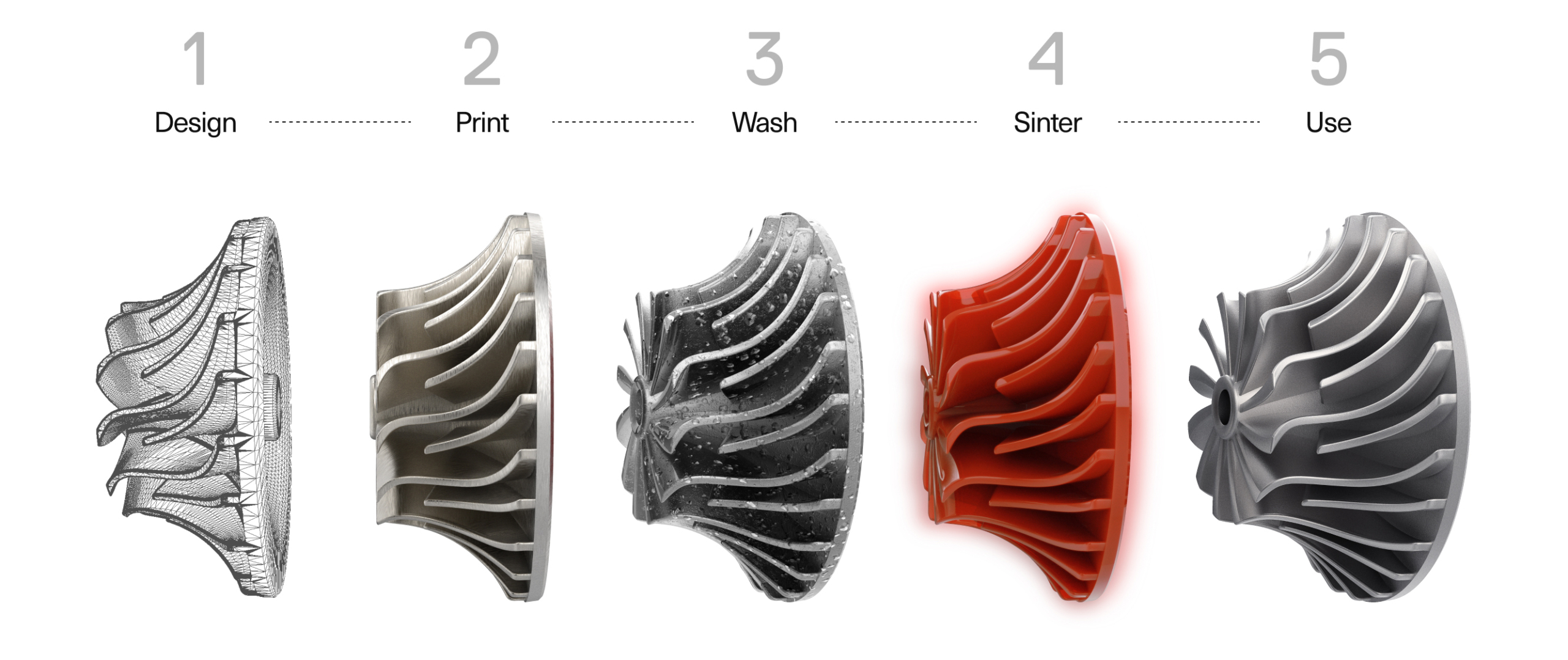

The Metal X is one of the most intuitive metal 3D printers available today. Print a wide range of materials from stainless steels to copper with minimal training on a closed workflow. Scaling up capacity is easy; just add printers.

The Metal X is designed to be safe to use and accessible for all fabricators. It costs several times less than DMLS metal 3D printing systems and requires no dedicated operator, no powder management system, and minimal PPE.

The Metal X is purpose-built for consistent part quality and a seamless user experience. Markforged combines superb software, materials research, and an advanced motion system to deliver industrial-grade parts quickly and reliably.

From stainless steel to copper,

we’re producing from a wide range of strong,

durable, and capable materials.

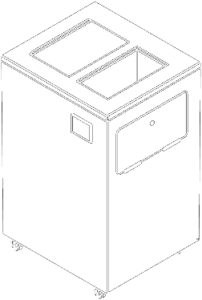

3D Printer

Physical Dimensions

| Width | 575 mm |

| Depth | 467 mm |

| Height | 1120 mm |

| Weight | 75 kg / 165 lbs |

Build Volume

| Width | 300 mm |

| Depth | 220 mm |

| Height | 180 mm |

Printing Process

Metal FFF

Z Layer Resolution

50 μm – 125 μm (Post-Sinter)

Printing Media

Bound Powder Filament

Internal Part Geometry

Closed Cell Infill (Triangular) or Solid Parts

Print Bed

Heated, Auto Leveling, Replaceable Print Sheets

Wash-1

External Dimensions

609 x 685 x 1,067 mm

Weight

136 kg (300 lbs)

Washing Time

12-72 hrs typical

Solvent

Opteon SF-79

Working Volume

356 x 254 x 203 mm

Sinter-2