Our company provides its committed partners with excellent quality cathode basic materials, which are an indispensable component of modern battery industry applications.

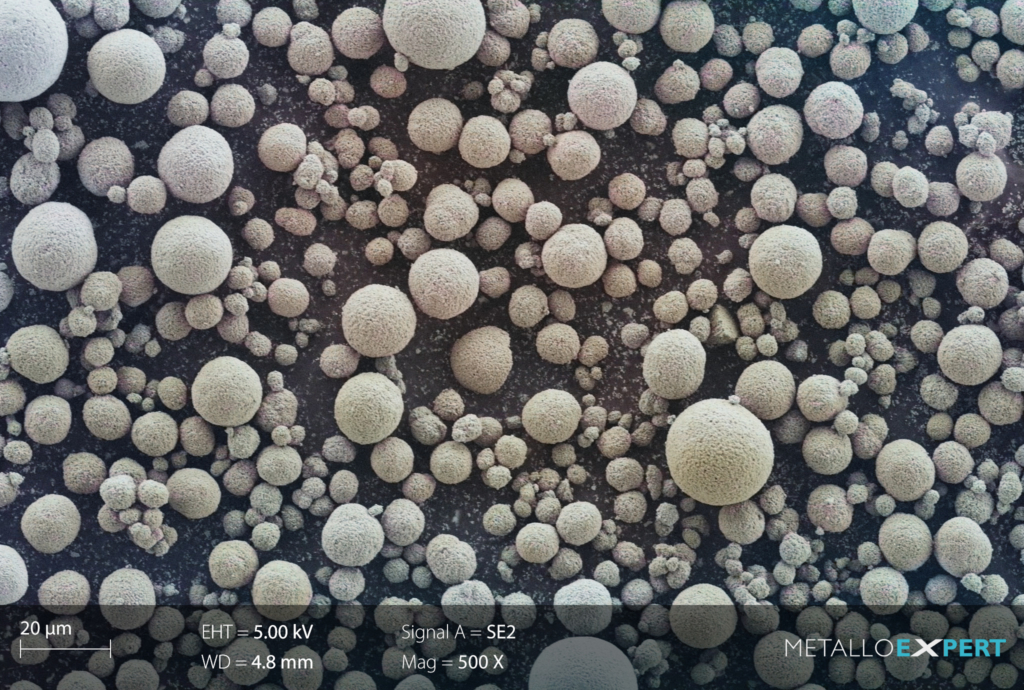

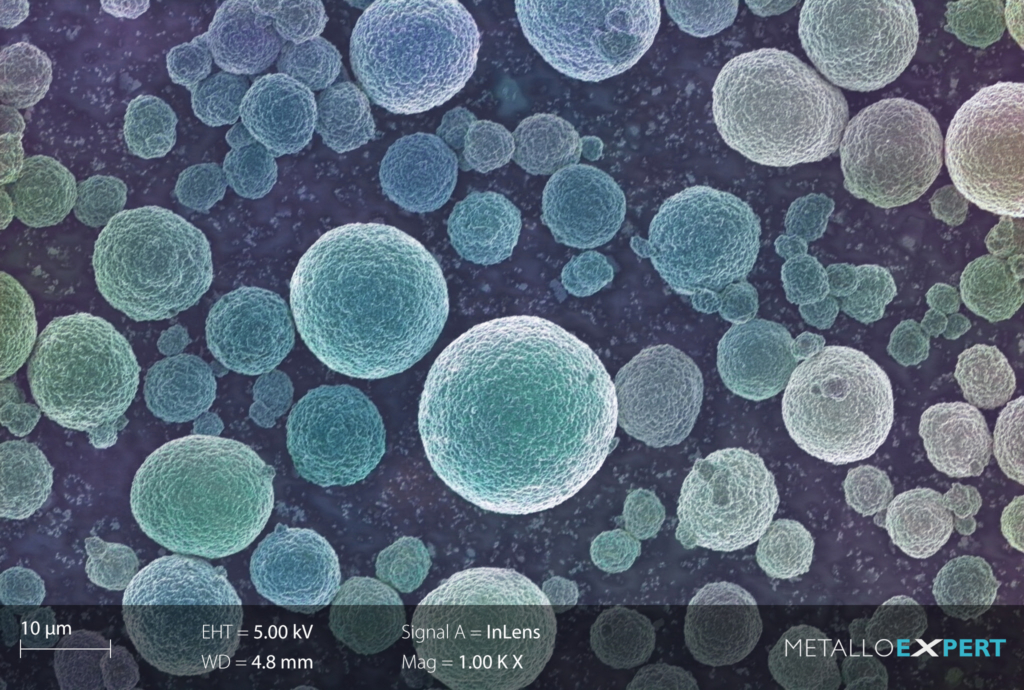

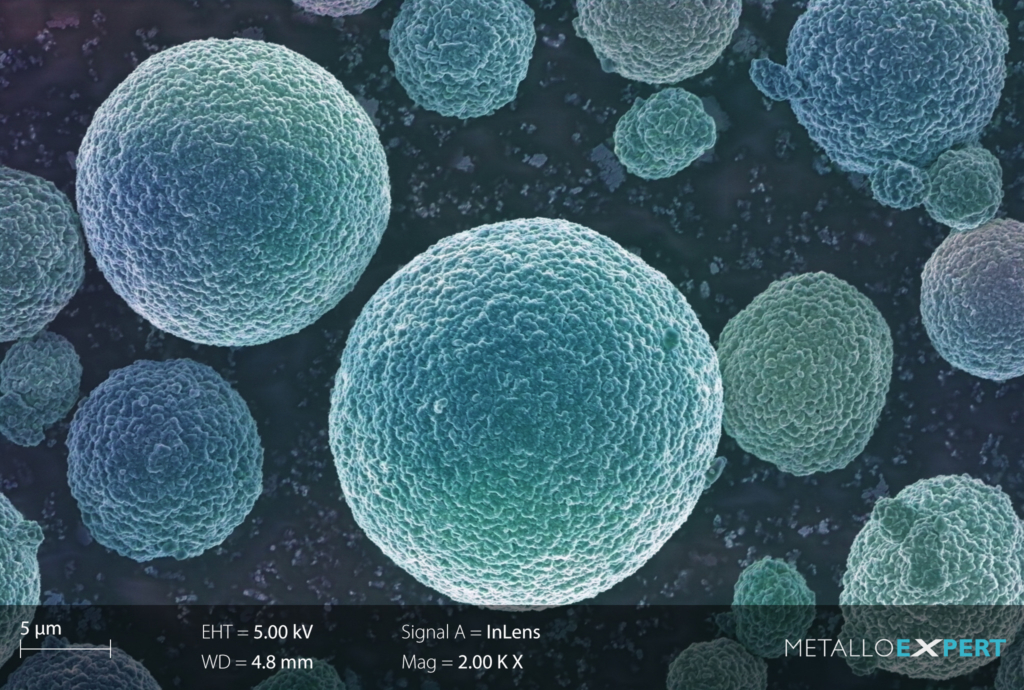

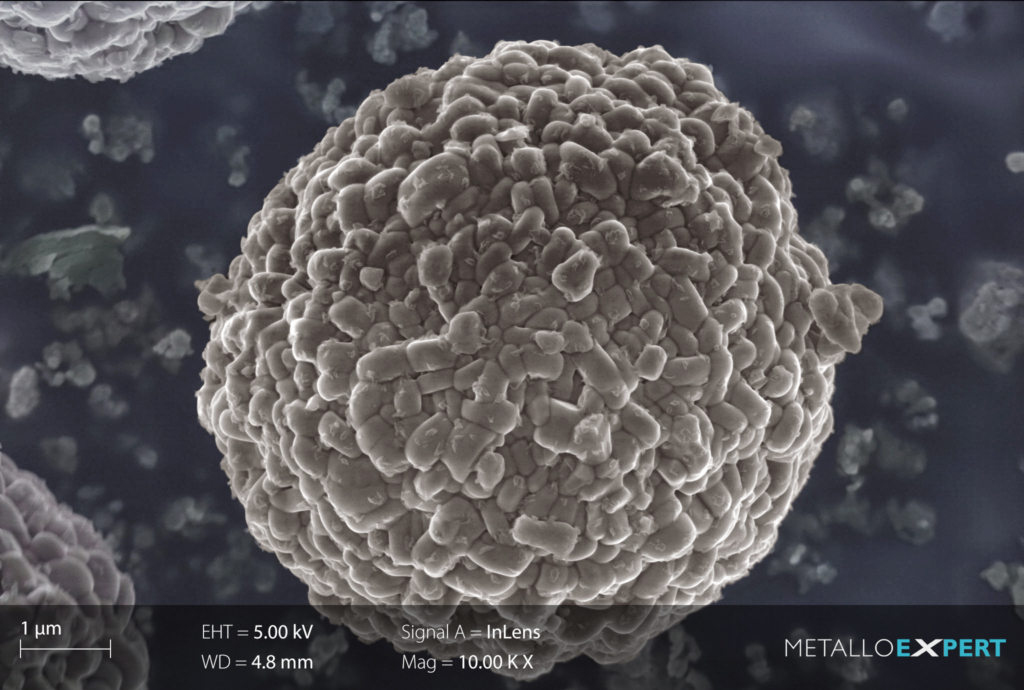

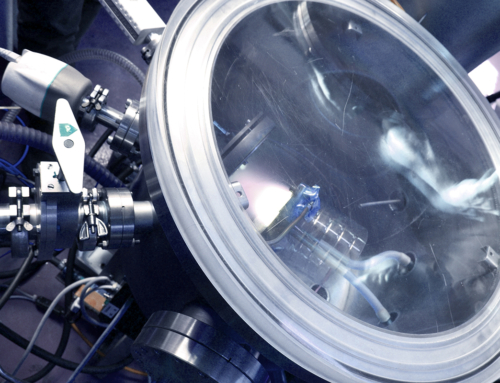

Cathode base material sintering

NMC811 cathode is a cathode material used in lithium-ion batteries that consists of nickel (Ni), manganese (Mn) and cobalt (Co) metals, with a ratio of 80% nickel, 10% manganese and 10% cobalt.

One of the key areas of cathode production is the mixing of lithium carbonate and pre-prepared metal oxides, followed by sintering at high temperatures (800–1000 °C). This heat treatment process is essential so that the metals and lithium atoms are well arranged and form a solid phase material. After sintering, the final NMC811 cathode material is formed.

Our company undertakes cathode material sintering for both its own and brought materials.

Cathode base material coating

The cathode plating process plays a critical role in improving the performance of lithium-ion batteries, especially in increasing the chemical stability and long-term cycle life of the cathode material. The purpose of the coating is to reduce direct contact with the electrolyte, which helps prevent unwanted chemical reactions such as dissolution or degradation.

Our company undertakes cathode material coating for both its own and brought materials.

High quality raw materials

We offer only high-quality raw materials that meet strict industry standards and regulations. Our products have excellent electrical conductivity and durability, ideal for various industrial uses.

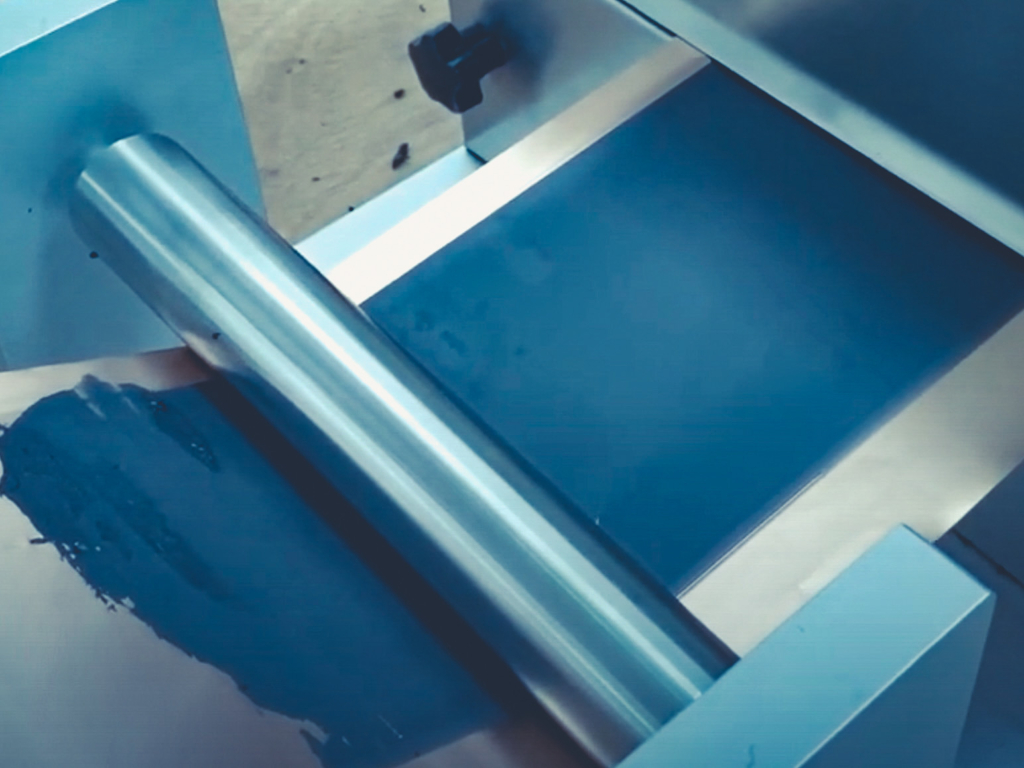

User-friendly packaging

In each case, the cathode coating is carried out with the user’s needs in mind, in a practical sheet form (200×400 mm) or rolled (200 mm x max. 3000 mm), in a flexible layer thickness (90-200 um) in one- or two-sided format, on 20 um thick aluminum foil.

Expert advice

Our team consists of experienced experts who are ready to help you choose the right raw material. Our consulting services ensure that the purchased products meet your specific requirements and areas of application.

Flexible shipping options

We provide fast and reliable delivery services to keep your production processes running smoothly. Our flexible delivery options allow raw materials to arrive to you on time.

Competitive price

We are aware that cost-effectiveness is crucial, so we offer competitive pricing without compromising on quality. You can get reliable raw materials that meet industry standards at an affordable price.

Sustainability

We are committed to environmental protection, which is why we carry out all our activities in a sustainable manner. During the production of our raw materials, we minimize our ecological footprint and support environmentally friendly solutions.