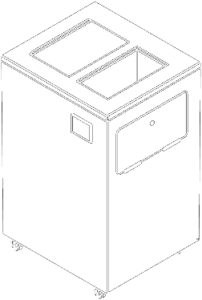

Physical Dimensions

| Width |

575 mm |

| Depth |

467 mm |

| Height |

1120 mm |

| Weight |

75 kg / 165 lbs |

Build Volume

| Width |

300 mm |

| Depth |

220 mm |

| Height |

180 mm |

Printing Process

Metal FFF

Z Layer Resolution

50 μm – 125 μm (Post-Sinter)

Printing Media

Bound Powder Filament

Internal Part Geometry

Closed Cell Infill (Triangular) or Solid Parts

Print Bed

Heated, Auto Leveling, Replaceable Print Sheets

Wash-1

External Dimensions

609 x 685 x 1,067 mm

Weight

136 kg (300 lbs)

Washing Time

12-72 hrs typical

Solvent

Opteon SF-79

Working Volume

356 x 254 x 203 mm

Sinter-2

External Dimensions

1,200 x 700 x 1,500 mm

Weight

350 kg (772 lbs)

Run Time

17-31 hours

Sintering Volume

18,356 cu cm

Peak Internal Temperature

1,300°C / 2,372°F

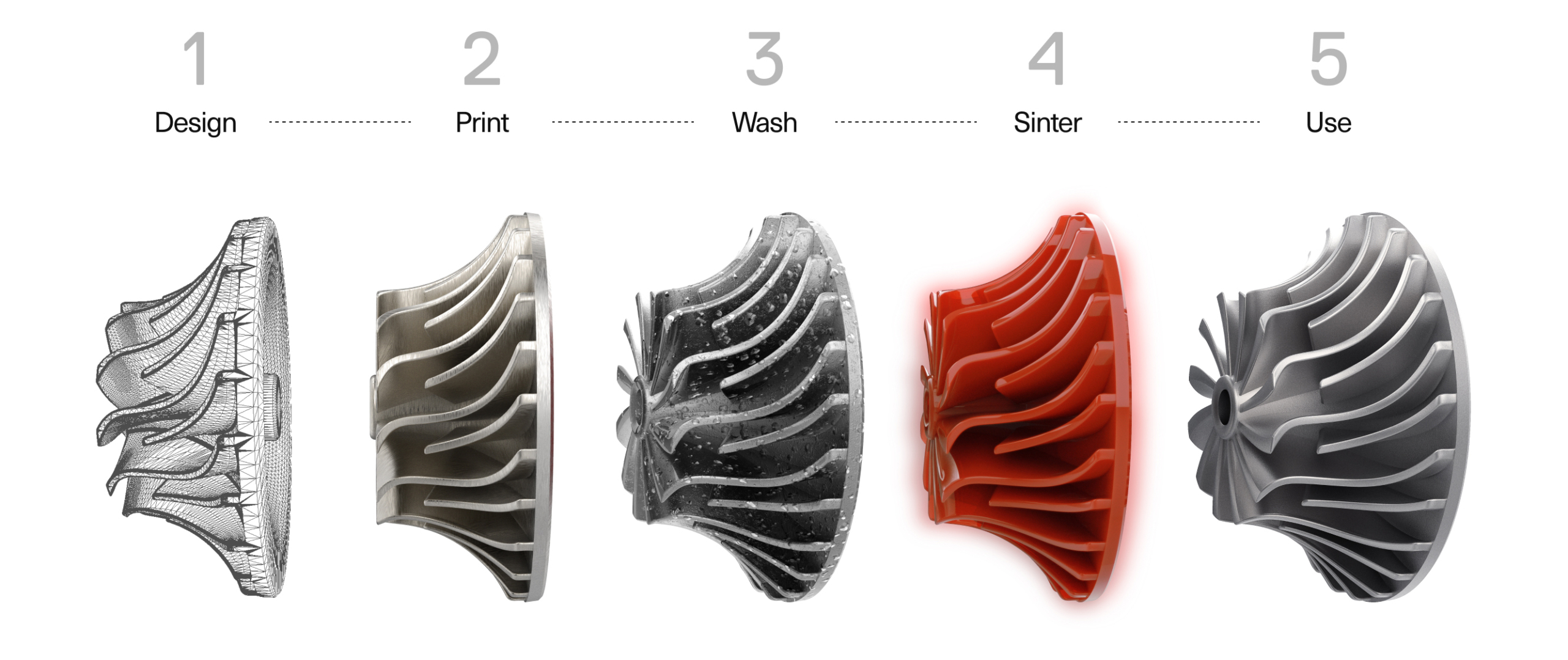

Metal X Printer

The Markforged Metal X is a new kind of metal printer. By printing metal powder bound in a plastic matrix, Markforged has eliminated many of the safety risks associated with traditional metal 3D printers. That means no loose powder, no lasers, and none of the traditional safety precautions. It’s safe to use in a shop environment with minimal facility upgrades.

In practice, the Metal X is essentially a very advanced FFF 3D printer. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the Metal X is equipped to reliably print you durable parts. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and brushes — accessible and trivial to swap.

Wash-1

The Wash-1 is a solvent-based debinding system. It primarily uses Opteon SF-79, a high-performance fluid designed to offer superior cleaning power, higher efficiency, and safety in an environmentally sustainable way — Opteon SF-80 or Tergo Metal Cleaning Fluid can be substituted if needed.

The Wash-1 operates with simple ventilation and features an extremely simple user experience. It’s been tested and verified as a shop-safe system.

Sinter-2 and Sinter-1

The Markforged Sinter-2 and Sinter-1 are highly optimized tube furnaces used for sintering 3D printed metal parts. They provide leading edge sintering reliability and run times and are equipped with advanced safety features. The Sinter-2 is more advanced than the Sinter-1 — featuring a larger working volume, more precise temperature control, and a mechanical door interlock.

The Sinter-1 and Sinter-2 typically have run times between 26 and 31 hours. However, the Sinter-2 can process small parts in express mode, where it can sinter up to 250g of parts in just 17 hours.